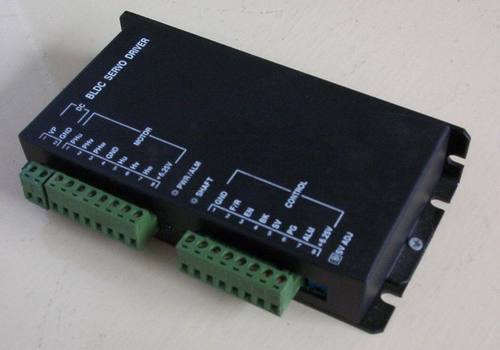

Brushless DC Servo Driver

Brushless DC Servo Driver Specification

- Display

- LED Indicator

- Switch Type

- Electronic

- Frequency

- Up to 20 kHz

- Current

- 2.5A to 20A (Model Dependent)

- Features

- Compact Design, High Efficiency, Quiet Operation, Overload Protection

- Usage & Applications

- Industrial Automation, Robotics, Pick & Place, Packaging, Medical Equipment

- Phase

- Three Phase

- Installation Type

- Panel Mount

- Sensor Type

- Hall Sensor/Encoder Compatible

- IP Rating

- IP20

- Product Type

- Brushless DC Servo Driver

- Operating Temperature

- 0C to 55C

- Working Temperature

- 0C to 55C

- Input

- DC Voltage

- Application

- Motion Control, Automation, Robotics, CNC Machinery

- Supply Voltage

- 24V/48V DC (Model Specific)

- Accuracy

- High Precision Control

- Dimension (L*W*H)

- 178mm x 130mm x 67mm

- Weight

- 1.25 kg

- Cooling Method

- Air Cooled

- Control Method

- Speed, Torque, and Position Control

- Supported Motor Power

- 50W to 750W

- Regeneration Resistor Support

- Yes

- Response Time

- <2 ms

- Signal Isolation

- Optically Isolated Input/Output

- Feedback Device Support

- Incremental Encoder, Hall Sensor

About Brushless DC Servo Driver

In this field we have got an international repute as one of the leading manufacturer and supplier of Brushless DC Servo Driver. Used in industrial and automotive motor, the driver is ideal for position & velocity control purposes. It is easy to servo tune by our driver, without the needs of a computer. We use optimum grade materials and components to manufacture the driver. Our Brushless DC Servo Driver is offered at the affordable prices.

Features:

-

External brake resistor

-

Differential signal interface

-

User friendly design

Brushless DC Servo Driver ( For motors 0.63 Nm to 2.8 Nm Torque )

Input Supply Voltage Upto +150V DC

Rating 600 watts , 1200 watts

Max Cont DC Current 8 Ampere

Min Pulse Width 5 microseconds

For Brushless motors from 40 watts upto 750 Watts.

Features

> Digital Control No Drift due to Ageing/Temperature

> Power & Control stages isolated for high noise immunity Precise position Control Within one Encoder count Pulse + Direction Signal for easy Stepper like performance. Position & Velocity control from Encoder signal alone No need for additional Analog (Tacho) feedback.

> Electronic Gearing Made simple with software selectable Pulse Multiplier

> Pulse Direction Line Driver Pulses , Max Frequency : 300 KHz

Totally Integrated Solution with CONTROL Panel

2) PLC , Motion Controllers

3) Transformer , Power Supplies

4) Stepper motors , Stepper Drives

5) Servo motor with Drives , CN1 connectors , Encoder and Motor Cables

Advanced Motion Control

Achieve superior performance in automation, robotics, and CNC applications using versatile speed, torque, and position control modes. The servo driver is equipped for high-precision operation, supporting motors from 50W to 750W, and integrates seamlessly with various feedback devices like incremental encoders and Hall sensors.

Robust Design for Industrial Use

The drivers compact structure allows effortless installation with panel mounting, while its IP20 rating ensures protection in indoor industrial environments. Equipped with overload protection and air cooling, it delivers reliable operation in ambient temperatures from 0C to 55C, handling demanding conditions effectively.

Intuitive Operation and Integration

Optically isolated inputs/outputs guarantee signal integrity and system safety, while the built-in LED indicator simplifies status monitoring. Designed for use with DC voltage supplies (24V/48V), the driver makes set-up and integration straightforward for manufacturers, service providers, and automation specialists.

FAQs of Brushless DC Servo Driver:

Q: How does the Brushless DC Servo Driver control speed, torque, and position?

A: This servo driver utilizes advanced control algorithms to manage speed, torque, and positional settings based on user input or automation requirements. It accepts signals from an incremental encoder or Hall sensor, processes this feedback, and dynamically adjusts motor drive for precise and reliable control.Q: What types of motors and applications is this driver compatible with?

A: The driver supports three-phase brushless DC motors with power ratings between 50W and 750W, covering a wide range of automation, robotics, CNC machinery, packaging, pick-and-place, and medical equipment applications. Its high-precision control is ideal for complex industrial operations requiring reliability and accuracy.Q: When should a regeneration resistor be used with this servo driver?

A: A regeneration resistor is recommended when the mechanical load decelerates rapidly or reverses direction, causing energy to flow back to the driver. This feature helps dissipate excess energy safely, protecting the driver and system from potential damage, especially in high-inertia or cyclic applications.Q: Where is signal isolation implemented in the system and why is it important?

A: Signal isolation is achieved through optically isolated inputs and outputs. This protects the control system from electrical noise, voltage spikes, and ground loops, ensuring safe and dependable communication between the servo driver and other equipment in the automation chain.Q: What is the recommended process for installing and configuring this driver?

A: For installation, securely mount the driver to a panel in a well-ventilated environment, ensuring supply voltage matches the model (24V or 48V DC). Connect compatible motors and feedback devices, then calibrate system parameters via the control interface. Use the LED indicator for operational status and troubleshooting.Q: How does the high response time benefit industrial automation processes?

A: A fast response time of less than 2 ms enables the servo driver to quickly react to command changes and feedback, resulting in smoother, more precise motion. This minimizes errors and enhances productivity in fast-paced automation, robotics, and CNC machine operations.Q: What are the main advantages of choosing this driver for industrial applications?

A: Key benefits include compact design, high efficiency, quiet operation, overload protection, and flexible control options. Combined with robust safety features, ease of integration, and compatibility with standard feedback devices, the driver is an exceptional choice for modern industrial automation projects in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brushless DC Driver for motor Category

ACS806 Leadshine BLDC Servo Drive

Product Type : BLDC Servo Drive

Features : Compact design High performance

Usage & Applications : Used for controlling brushless DC servo motors

Output : 50W to 400W

Application : Industrial Automation

ACS306 Leadshine BLDC Servo Drive

Product Type : BLDC Servo Drive

Features : Supports a wide range of power ratings from 25W to 130W compact design

Usage & Applications : Servo control systems for complex motion applications

Application : Used for Brushless DC motors in industrial automation applications

ACS606 Leadshine BLDC Driver

Product Type : BLDC Driver

Features : Highly reliable high performance BLDC driver

Usage & Applications : Driving Brushless DC Motors

Output : 25W

GST : 27AADCT3013C1ZX

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS