RTD-PT

RTD-PT Specification

- Features

- High Accuracy, Long Life, Vibration Resistant, Quick Response

- Mounting Type

- Threaded / Flanged / Fixed

- Phase

- Single/Three Phase

- IP Rating

- IP65

- Connectivity Type

- Two-wire / Three-wire / Four-wire

- Cable Length

- 1 m / 2 m / Customized

- Remote Control

- Yes

- Control Type

- Analog / Digital

- Weight

- Approx. 200 g

- Frequency

- 50/60 Hz

- Automation Grade

- Automatic

- Application

- Temperature Measurement in Industrial Processes

- Sensor Type

- RTD (Resistance Temperature Detector)

- Material

- Platinum (Pt100 Element)

- Power

- Electrical, Low Voltage

- Temperature

- -50C to 250C (Standard)

- Voltage

- 12V/24V/220V (As Required)

- Sheath Material

- Stainless Steel (SS304/SS316)

- Insulation Resistance

- >100 M at 500V DC

- Connection Head

- Aluminium Die Cast / ABS

- Element Type

- Pt100, Class A/B as per IEC 60751

- Termination

- Ceramic Terminal Block / Lead Wire

- Response Time

- <5 seconds (in Water)

About RTD-PT

DELTA Offer Temperature Modules of Various Series

- DTA Series

- DTC Series

- DTV Series

- DTE Series

- DTD Series

- DTB Series

| DELTA Temperature Modules/Units RTD/PT100/Thermocouple | |||

| DTA Series | With / Without RS485 Communication Door Mounting type | DTA4848R0 DTA4848V0 DTA4848C0 DTA7272R0 DTA7272V0 DTA7272C0 DTA9696R0 DTA9696V0 DTA9696C0 DTA4896R0 DTA4896V0 DTA4896C0 DTA4848R1 DTA4848V1 | |

| DTC Series | Compact type with RS485 Communication | DTC1000R DTC2000R DTC1000V DTC2000V DTC1000C DTC2000C DTC1000L DTC2000L | |

| DTV Series | For Valve Control | DTV4896R/V DTV9696R/C | |

| DTD Series | With Analog Input & without Communication | DTD4848R0/V0 DTD4896R0/V0 | |

| DTE Series | For Multiple Extension | DTE20T DTE20R DTE20V DTE20L DTE20C DTE2DS | |

| DTB Series | Advanced type with RS485 | DTB4824RR DTB4824CR DTB4824CV DTB4824LR DTB4824LV DTB4824VV | |

|

For Details Contact : 09867528528 / 09619312807 /09869279756 / 022-27464402

| |||

High-Precision Platinum Sensing

This RTD sensor employs a Pt100 element, known for stability and accuracy, ensuring temperature readings conform to IEC 60751 Class A/B standards. It is ideal for critical industrial temperature monitoring and process control, where exact data is essential to maintain operational efficiency.

Robust and Adaptable Construction

Encased in SS304 or SS316 sheath with a choice of connection heads (aluminium die-cast or ABS), the RTD-PT is engineered for durability and reliability. Its IP65 rating protects against dust and water ingress, while its resistance to vibration and rapid response make it suitable for demanding environments.

Flexible Integration and Customization

Available in threaded, flanged, or fixed mounting, this sensor integrates seamlessly into existing setups. With options for termination (ceramic terminal block or lead wire), connectivity, and cable length, its tailored for diverse installation requirements across automation and process control systems.

FAQs of RTD-PT:

Q: How is the RTD-PT with Pt100 Element installed in industrial environments?

A: The RTD-PT can be installed using threaded, flanged, or fixed mounting methods, allowing for secure fitting in a wide variety of process setups. It is typically positioned where precise temperature measurement is required, such as pipelines, tanks, or industrial equipment, and integrates with process control systems through its selectable termination and wiring options.Q: What are the key benefits of using a Class A/B Pt100 sensor as per IEC 60751?

A: Using a Class A/B Pt100 sensor ensures high measurement accuracy and stable performance over time. Conformance with IEC 60751 guarantees standardized tolerances, making the sensor reliable for precise temperature monitoring tasks in critical industrial applications.Q: When should I choose SS304 versus SS316 sheath material for this RTD?

A: SS304 is suitable for general industrial use, offering good corrosion resistance. For more demanding environments with higher corrosion risks or exposure to chemicals (such as in marine or chemical processing sectors), SS316 is preferred due to its enhanced protective properties.Q: Where can this RTD-PT be utilized within industrial processes?

A: This sensor is versatile and can be deployed wherever accurate temperature measurement is needed, such as in food processing, chemical plants, refineries, power generation, and HVAC systems. Its fast response and high insulation resistance make it effective in both standard and harsh operational conditions.Q: What is the typical process for connecting and commissioning this RTD sensor?

A: Connection involves wiring to a control or measurement system using a ceramic terminal block or lead wires, followed by selecting the appropriate two, three, or four-wire configuration. After physical installation with the chosen mounting type, the sensor is integrated into the process control loop, and operational checks ensure accurate performance.Q: How does the RTD-PT maintain long life and high accuracy in challenging industrial settings?

A: Its robust stainless steel sheath, high insulation resistance (>100 M at 500V DC), and protection rating (IP65) safeguard against environmental factors. Vibration resistance, rapid response time, and compliance with international standards contribute to its long-term, consistent accuracy.Q: What application advantages does the quick response time offer?

A: With a response time of under 5 seconds in water, the RTD-PT rapidly detects temperature shifts, allowing for faster system adjustments and enhanced safety in process control. This agility is particularly beneficial in situations where real-time monitoring and swift action are crucial.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PLC HMI Controllers Category

Delta TP02G-AS1

Voltage : 24V DC

Power : 24V DC

Temperature : 050C

Warranty : 1 Year

Material : Plastic

Connectivity Type : Wired

Delta HMI DOPB07S411

Voltage : 24V DC

Power : 24V DC

Temperature : 0C to 50C

Warranty : 1 Year

Material : Plastic and Metal

Connectivity Type : Ethernet USB

Delta DOP-B05S211

Voltage : 24V DC

Power : 24V DC

Temperature : 0C to 50C

Warranty : 12 months

Material : Plastic housing

Connectivity Type : Ethernet USB

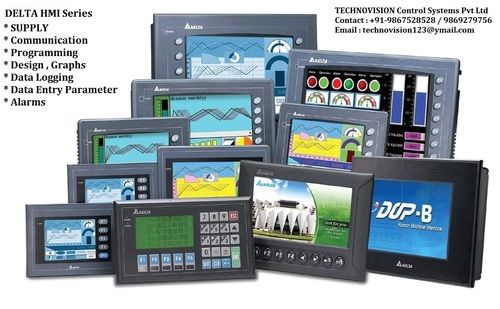

DELTA HMI Solutions

Voltage : Standard Voltage Range

Power : Standard Supply

Temperature : Operational within Industrial Standards

Warranty : Warranty as per manufacturer policy

Material : Durable Plastic

Connectivity Type : Wired

GST : 27AADCT3013C1ZX

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS