RTD-PT

RTD-PT Specification

- IP Rating

- IP65

- Remote Control

- Yes

- Control Type

- Analog

- Automation Grade

- Automatic

- Mounting Type

- Flange / Threaded

- Application

- Temperature Measurement in Process Industries

- Cable Length

- 2 Meter

- Sensor Type

- PT-100

- Connectivity Type

- 2/3 Wire

- Frequency

- 50/60 Hz

- Weight

- 150g

- Phase

- Single Phase

- Features

- High Accuracy, Robust Construction, Long Life

- Material

- Stainless Steel

- Power

- 0.5W

- Temperature

- -50C to 250C

- Voltage

- 220V AC

About RTD-PT

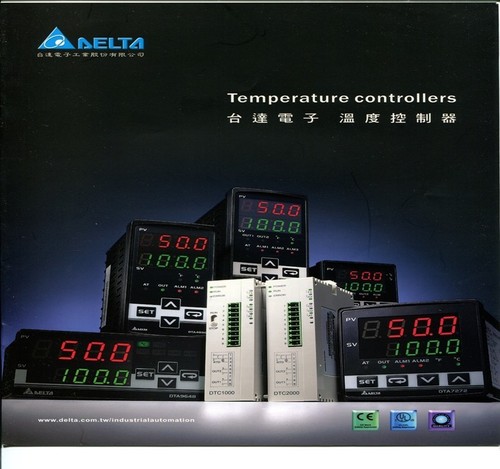

DELTA Offer Temperature Modules of Various Series

- DTA Series

- DTC Series

- DTV Series

- DTE Series

- DTD Series

- DTB Series

| DELTA Temperature Modules/Units RTD/PT100/Thermocouple | |||

| DTA Series | With / Without RS485 Communication Door Mounting type | DTA4848R0 DTA4848V0 DTA4848C0 DTA7272R0 DTA7272V0 DTA7272C0 DTA9696R0 DTA9696V0 DTA9696C0 DTA4896R0 DTA4896V0 DTA4896C0 DTA4848R1 DTA4848V1 | |

| DTC Series | Compact type with RS485 Communication | DTC1000R DTC2000R DTC1000V DTC2000V DTC1000C DTC2000C DTC1000L DTC2000L | |

| DTV Series | For Valve Control | DTV4896R/V DTV9696R/C | |

| DTD Series | With Analog Input & without Communication | DTD4848R0/V0 DTD4896R0/V0 | |

| DTE Series | For Multiple Extension | DTE20T DTE20R DTE20V DTE20L DTE20C DTE2DS | |

| DTB Series | Advanced type with RS485 | DTB4824RR DTB4824CR DTB4824CV DTB4824LR DTB4824LV DTB4824VV | |

|

For Details Contact : 09867528528 / 09619312807 /09869279756 / 022-27464402

| |||

Versatile Sensing for Process Industries

Our RTD-PT sensor is meticulously crafted for temperature measurement applications across diverse process industries. With customizable sizes, mounting options, and weatherproof or flameproof protection, it adapts effortlessly to site-specific requirements. The choice of ceramic or magnesium oxide insulation ensures optimal thermal response and robust insulation against harsh industrial conditions.

Precision, Durability, and Safety Combined

Employing a PT-100 sensor element in either simplex or duplex form, this device offers precise resistance-based temperature readings. The durable stainless steel construction, coupled with an IP65 enclosure, delivers long-lasting protection and stable performance in demanding environments. Installation is streamlined owing to options like flange or threaded mount, while the analog output ensures compatibility with standard control systems.

FAQs of RTD-PT:

Q: How is the RTD-PT sensor installed and configured in industrial setups?

A: The RTD-PT sensor can be installed using either a flange or threaded mounting, depending on site requirements. Probe length and sheath diameter can be customized for optimal placement. Configuration is straightforward, with 2 or 3 wire connectivity for integrating into analog control systems.Q: What are the main advantages of using the RTD-PT for temperature measurement?

A: Key benefits include high accuracy, rapid response time (less than 4 seconds), robust stainless steel construction for durability, and long service life. The sensors weatherproof and flameproof options ensure reliable operation in challenging industrial environments.Q: When should I choose simplex versus duplex element configuration?

A: Select simplex configuration for single-point temperature measurement. Opt for duplex if you require redundancy or simultaneous dual readings at the same location, enhancing safety and backup in critical processes.Q: Where can the RTD-PT sensor be utilized?

A: This sensor is suitable for process industries such as chemical, pharmaceutical, petrochemical, and food processing plants, where precise and reliable temperature monitoring is essential.Q: What is the process for customizing the RTD-PT sensor to my application?

A: Customization involves specifying sheath diameter, probe length, insulation type, lead material, and mounting method. Manufacturers and suppliers in India can help tailor the sensor according to your precise operational requirements.Q: How does the ceramic/MGO insulation improve the performance of the RTD-PT?

A: Ceramic and magnesium oxide insulation provide high dielectric strength and superior thermal conductivity. This ensures accurate readings, quick response, and protection against electrical and thermal stresses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PLC HMI Controllers Category

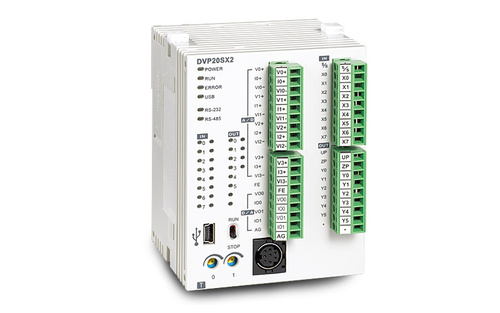

Delta PLC DVP20SX2

Connectivity Type : Wired

Features : Compact size 20 points I/O Highly efficient

Mounting Type : DIN Rail

Control Type : Programmable Logic Controller

Automation Grade : High

Application : Industrial automation

Delta Display TP08GBT2

Connectivity Type : RS232, RS485, Ethernet

Features : Color Touchscreen, High Reliability, Programmable, Easy Integration

Mounting Type : Panel Mount

Control Type : Touch Panel

Automation Grade : Automatic

Application : Industrial Automation

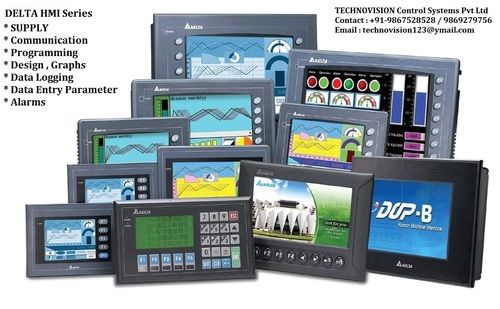

DELTA HMI Solutions

Connectivity Type : Wired

Features : Communication Programming Design Graphics Data Logging Data Entry Parameter Alarms

Mounting Type : Panel Mount

Control Type : Touch Control

Automation Grade : Fully Automated

Application : Industrial Automation

Delta Motion Controller DVP10PM

Connectivity Type : Wired

Features : Compact Design High Performance

Mounting Type : DIN Rail

Control Type : Digital

Automation Grade : Industrial

Application : Motion Control

GST : 27AADCT3013C1ZX

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS