Delta PLC DVP20EH3

Delta PLC DVP20EH3 Specification

- Phase

- Single Phase

- Control Type

- Programmable Logic Controller (PLC)

- Sensor Type

- Supports NPN/PNP Sensor Inputs

- Features

- High speed and stable operation, multiple communication ports, expandable I/O, datalogging, PID control

- Frequency

- 50/60 Hz

- IP Rating

- IP20

- Weight

- Approx. 0.49 kg

- Remote Control

- Yes

- Application

- Industrial Automation, Machinery Control

- Mounting Type

- DIN Rail Mount

- Automation Grade

- Automatic

- Speed Range

- Programmable, depends on application software

- Material

- ABS Plastic and Metal

- Power

- 24 VDC, 5W

- Temperature

- 0C to 55C (Operating)

- Voltage

- 24V DC

- Response Time

- Less than 0.5 microseconds/instruction

- Programming Software

- WPLSoft, ISPSoft

- Communication Protocols

- Modbus, ASCII, Ethernet/IP (with extension module)

- Data Register

- 10k words

- Program Capacity

- 16k steps

- Backup Battery

- Supported (for program/data retention)

- Model Number

- DVP20EH3

- Dimension (W x H x D)

- 90 x 90 x 55 mm

- Output Type

- Relay/Transistor (Depending on variant)

- Input Type

- Digital

- Number of I/O

- 20 (12 digital input, 8 digital output)

- Extension Capability

- Up to 512 I/O points with expansion modules

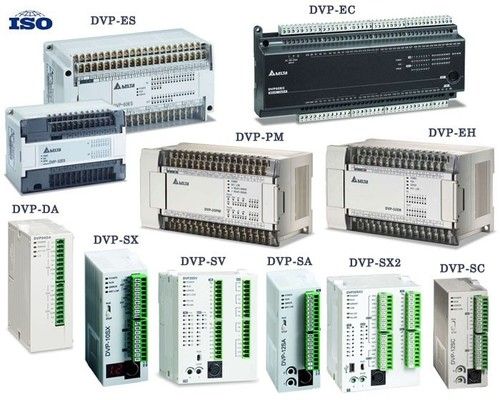

About Delta PLC DVP20EH3

Delta PLC DVP20EH3

- High-speed pulse output: 4 sets of 200kHz pulse output (DVP40/48/64/80EH00T3)

- Supports max. 4 hardware 200kHz high-speed counters

- Increases many motion control instructions to meet the applications that require high-speed and high-precision

- positioning control such as labeling machines, packaging machines and printing machines

- Offers linear / arc interpolation motion control

- Provides up to 16 external interrupt pointers

Complete Program Protection

Auto backup function to prevent losing programs and data even when the battery runs out

Second copy function provides a backup for extra insurance in the event that one set of programs and data are damaged

Up to 4-level password protection protects your source programs and intellectual property

Outstanding Operation Performance

CPU + ASIC dual processors support floating point operations.

The max. execution speed of basic instructions is able to reach 0.24s.

Flexible Function Extension Modules & Cards

The multiple selections of extension modules and function cards provide analog I/O, temperature measurement, additional single-axis motion control, high-speed counting, 3rd serial communication port and Ethernet communication card are available.

PLC-Link

C-Link allows the user to link up a max. 32 units to the network without having to install extra communication extension modules.

Brand-New High-Speed Extension Modules

Versatile I/O and Expansion

The DVP20EH3 provides 20 built-in digital I/O points with options for relay or transistor outputs, giving users flexibility for different types of machinery and manufacturing systems. For larger applications, the expansion capability allows integration of modules for up to 512 I/O points, accommodating complex control requirements.

High-Speed, Reliable Control

Equipped with a response time of less than 0.5 microseconds per instruction, the DVP20EH3 ensures that control tasks are executed swiftly and accurately. This high-speed processing is essential for automation tasks that demand immediate feedback and precise actuation, contributing to better productivity and process reliability.

Advanced Connectivity and Remote Management

Built-in support for Modbus and ASCII protocols, along with optional Ethernet/IP connectivity via extension modules, empowers users to seamlessly connect the PLC to diverse automation networks. With remote control features, the DVP20EH3 can be managed, programmed, and monitored from afar, streamlining maintenance and operations.

FAQs of Delta PLC DVP20EH3:

Q: How can I expand the number of I/O points on the DVP20EH3 PLC?

A: The DVP20EH3 supports expansion up to 512 I/O points using compatible expansion modules available from Delta. Simply connect additional expansion modules to the main unit to increase input and output capacity as your application requirements grow.Q: What programming software is compatible with the DVP20EH3?

A: You can program the DVP20EH3 using Deltas WPLSoft or ISPSoft software. Both platforms provide user-friendly interfaces for ladder logic, function blocks, and structured text programming, making setup and troubleshooting more efficient.Q: When should I use relay output versus transistor output variants of the DVP20EH3?

A: Choose relay output variants for controlling devices that require electrical isolation or higher voltage switching (such as solenoids or contactors). Transistor outputs are ideal for fast-switching, low-voltage applications like controlling LEDs, buzzers, or small motors requiring rapid response.Q: Where can I use the DVP20EH3 in industrial applications?

A: The DVP20EH3 is suitable for a wide range of industrial automation tasks, including machinery control, assembly lines, packaging systems, and process automation. Its compact size and DIN rail mounting make it fit seamlessly into various control panels and factory settings.Q: What communication protocols are supported by the DVP20EH3, and how do they benefit my system?

A: The DVP20EH3 supports Modbus, ASCII, and, with extension, Ethernet/IP protocols. These protocols facilitate easy integration with other controllers, HMIs, and SCADA systems, enabling efficient data exchange and remote monitoring for enhanced operational efficiency.Q: How does the backup battery benefit the DVP20EH3s operation?

A: The backup battery ensures that your program and data registers are retained even during power outages. This minimizes downtime and prevents data loss, safeguarding critical process automation and system continuity.Q: What steps are involved in setting up the DVP20EH3 for industrial automation?

A: Begin by mounting the PLC on a DIN rail, wiring inputs and outputs as per your application, and connecting necessary expansion modules. Next, use WPLSoft or ISPSoft to configure the program logic, and set up communication parameters. Once programmed, test and deploy the PLC to monitor and control your automation process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PLC HMI Controllers Category

DELTA

Voltage : 3 Phase 380V 480V AC

Temperature : 10C to +50C

Processor Type : Digital Signal Processor (DSP)

Features : Overload Protection, Energy Saving, Fault Protection

Control Type : Vector Control / V/F Control

Frequency : 50/60 Hz

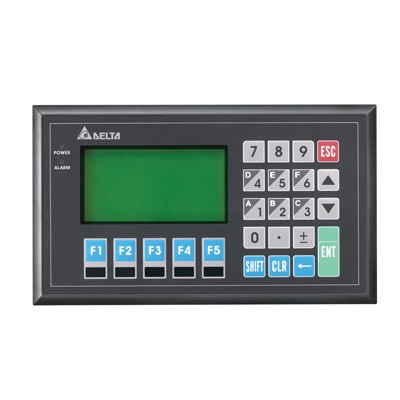

Delta TP08G-BT2

Voltage : 24 V DC

Temperature : 0C to 50C

Processor Type : Microcontrollerbased

Features : Programmable Userfriendly interface

Control Type : Keypad and Display

Frequency : 50/60 Hz

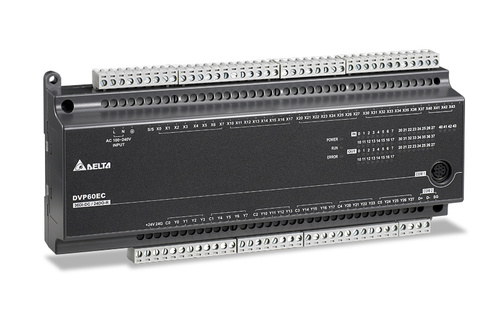

Delta PLC DVP14EC3

Voltage : 100240V AC

Temperature : 0 to 55C

Processor Type : 32bit CPU

Features : Compact design Highspeed processing Ethernet connectivity

Control Type : PLC

Frequency : 5060 Hz

Delta DOP-B10S615

Voltage : 24V DC

Temperature : 0C to 50C

Processor Type : ARMbased processor

Features : 10.1inch touchscreen Ethernet and USB support highresolution display

Control Type : Touchscreen

Frequency : Variable

GST : 27AADCT3013C1ZX

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS