Syringe Placing Machine

Syringe Placing Machine Specification

- Starting Type

- Automatic

- Features

- Automatic, Low Noise, Durable, Precision Placing

- Motor Type

- Induction Motor

- Rated Frequency

- 50 Hz

- Power Rating

- 2.5 kW

- Pressure

- 0.5 MPa

- Torque

- 18 Nm

- Horse Power

- 3 HP

- Poles Number

- 4

- Sealed Type

- Sealed

- Bearing Type

- Double Sealed Ball Bearing

- Cooling Method

- Air Cooled

- Noise Level

- <75 dB

- Efficacy

- Up to 98%

- Rated Voltage

- 220 V

- Ambient Temperature

- 5C to 40C

- Current Type

- AC

- Product Type

- Syringe Placing Machine

- Output Power

- 2 kW

- Frequency (MHz)

- 50 Hz

- Protect Feature

- Overload Protection

- Phase

- Three Phase

- Speed

- 60 syringes/min

- Power

- 2.5 kW

- Color

- Blue and White

- Dimension (L*W*H)

- 1200 x 800 x 1500 mm

- Weight

- 350 kg

- Shaft Diameter

- 28 mm

- Mounting Type

- Floor Mounted

- IP Rating

- IP54

About Syringe Placing Machine

With vast industry knowledge, we are presenting a high quality range of Syringe Placing Machine. The machine is manufactured in our sophisticated production unit, using superior quality materials and components. The quality inspectors check the machine on performance and construction parameters to provide a defect free range to the clients. We offer the Syringe Placing Machine at affordable prices and deliver to clients within the given time frame.

Features:

-

Hassle free performance

-

Easy maintenance

-

High working efficiency

Syringe Placing machine

Programming , Installation , Commissioning , Wiring , Documentation Circuit Diagram , Panel Building Design

Control Panel Building for Various Industries

) Heavy Metal Industries

2)TubemillApplications

3) FurnaceHeater Switchgear Panels

4) HVAC applications

5)Printing , Packaging , Automobiles , Steel , Textile , Tiles and Various other Industries.

Total Turnkey Project Solutions

Programming , Installation , Commissioning , Wiring , Documentation Circuit Diagram , Panel Building Design

Automated Precision Placement

This advanced syringe placing machine employs a digital PLC control system and a vibration feeder hopper to ensure fast and precise syringe placement. The automation dramatically reduces manual error, boosts productivity, and maintains consistent quality, crucial for high-demand medical assembly lines.

Robust Stainless Steel Construction

Built with SS304 stainless steel, the machine withstands rigorous production schedules while ensuring longevity and durability. Its IP54 rating provides strong protection against dust and splashes, suitable for strict hygiene and safety standards in medical device manufacturing environments.

User-Friendly and Safe Operation

Equipped with a digital touch screen display, emergency stop functions, and safety interlocks, this machine enables easy and secure operation by a single operator. The centralized lubrication system further simplifies maintenance, minimizing downtime and ensuring operational continuity.

FAQs of Syringe Placing Machine:

Q: How does the Syringe Placing Machine ensure consistent and accurate syringe placement?

A: The machine combines a vibration feeder hopper with a PLC-controlled system and digital touch screen interface. This setup maintains precise positioning and timing, allowing automated placement of syringes with up to 98% efficacy at speeds of 60 syringes per minute.Q: What safety features are integrated into the machine for operator protection?

A: Safety is ensured with emergency stop functionality, safety interlocks, and an IP54 enclosure. These features protect operators from accidental machine startup and provide reliable protection in high-paced industrial environments.Q: When is maintenance typically required, and how easy is it to perform?

A: Routine maintenance is minimized thanks to centralized lubrication and durable SS304 construction. When necessary, its operator-friendly design and clear digital display make servicing straightforward, typically requiring only one operator and minimal downtime.Q: Where can this machine be used most effectively?

A: This machine is ideal for pharmaceutical manufacturing units, medical device assembly lines, or any setting where precise and hygienic handling of syringes is essential. Its compact design allows floor-mounted installation in various facility layouts.Q: What is the process for starting and operating the Syringe Placing Machine?

A: The machine is started automatically via its PLC control system. An operator uses the digital touch screen to configure settings, and the flat belt conveyor, guided by the vibration feeder, begins high-speed syringe placement as per programmed instructions.Q: What are the main benefits of using this automatic syringe placing system?

A: Key benefits include rapid processing speed, reduced manual labor, heightened safety, and error minimization. The centralized lubrication system ensures long-term reliability, while precise placement enhances the overall efficiency and quality of medical assembly processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Integration Projects Category

ELB Schliff Surface Grinder Controller

Protect Feature : Not available, Other

Voltage : Not available

Starting Type : Not available

Power : Not available

Poles Number : Not available, Other

Mounting Type : Not available

Ampoule Machine Controller

Protect Feature : Other, Overload Protection

Voltage : 220V

Starting Type : Soft Start

Power : 30W

Poles Number : 2

Mounting Type : Panel Mount

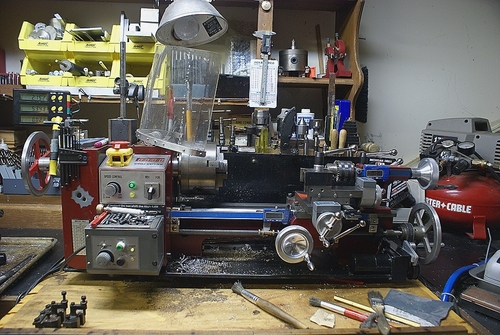

Lathe Machine Controller

Protect Feature : Other, Overload and Short Circuit Protection

Voltage : 415 V

Starting Type : Direct On Line (DOL)

Power : 1.5 kW

Poles Number : 4

Mounting Type : Base Mounted

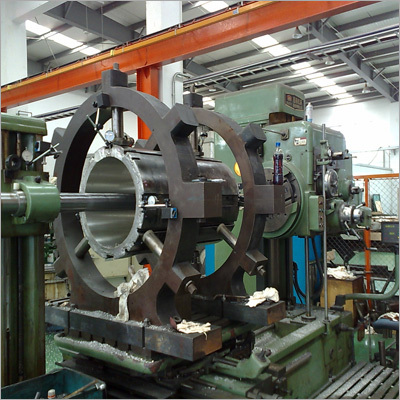

Boring Machine Control System

Protect Feature : Other, Overload, Short Circuit, Overheat

Voltage : 380 V AC

Starting Type : Soft Start

Power : 3.5 kW

Poles Number : 4

Mounting Type : Panel Mount

GST : 27AADCT3013C1ZX

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS